EWASG

Here's the English translation of your request:

"Hello, I am using the **EWASG module** for **hydrogen storage in an aquifer**, but the OUT file is reporting an error. Did I set any parameters incorrectly? I hope to get help. Below is a screenshot of the error message, **attached with the input files**."image

5 replies

-

The message tells you there is a phase transition from L to L+G at the very first iteration, which is not allowed. The appearance of gas phase occurs because of a wrong initialization of the third primary variable X3=10.0, which makes no sense, as it is interpreted as the mass fraction of H2 in the liquid phase.

$$$$$$$$$$$ GAS PHASE EVOLVES AT ELEMENT *000 0* $$$$$ XH2 = 0.100000E+02 PX = 0.106144E+08 Pa PBOIL = 0.817076E+10 Pa

}}}}}}}}}}} ERRONEOUS DATA INITIALIZATION }}}}}}}}}} STOP EXECUTION----------I guess you want to initialize a single-liquid system for which X3 should be the mass fraction of hydrogen dissolved in the aqueous phase. This value must be lower than H2 solubility at local P&T conditions.

Have a look to the user's guide and the informative printout in the output file.

***************************************************************************************

THE PRIMARY VARIABLES ARE

P - PRESSURE XSM - SALT MASS FRACTION IN LIQUID (XS) OR SOLID SATURATION (SS+10.)

X3 - NCG MASS FRACTION OR SG+10. - GAS PHASE SATURATION + 10. T - TEMPERATURE***************************************************************************************

* COMPONENTS * * FLUID PHASE CONDITION PRIMARY VARIABLES * ************************************************************************************** *

* # 1 - WATER * * SINGLE-PHASE GAS P, XSM, X3, T *

* # 2 - NaCl * * SINGLE-PHASE LIQUID P, XSM, X3, T *

* # 3 - NCG * * TWO-PHASE P, XSM, SG+10., T *

* # 4 - HEAT ****************************************************************************************

Be aware that the thermodynamic approach in EWASG is not accurate at very high partial pressures of the NCG, such as in your simulation of H2 storage in an aquifer with pressures around 100 bar.

Regards,

Alfredo

-

Dear Gao,

H2 was included as an optional NCG inside EWASG with a treatment of water-H2 mixture very similar to what is done in EOS5.

The density of gaseous H2 is evaluated with the ideal gas law in both EOS.

The viscosity of gaseous H2 is evaluated with the same routine using data from Vargaftik (1975).

The enthalpy of gaseous H2 is computed using a constant specific heat in EOS5, while is computed according to Irvine and Liley (1984) correlation in EWASG.

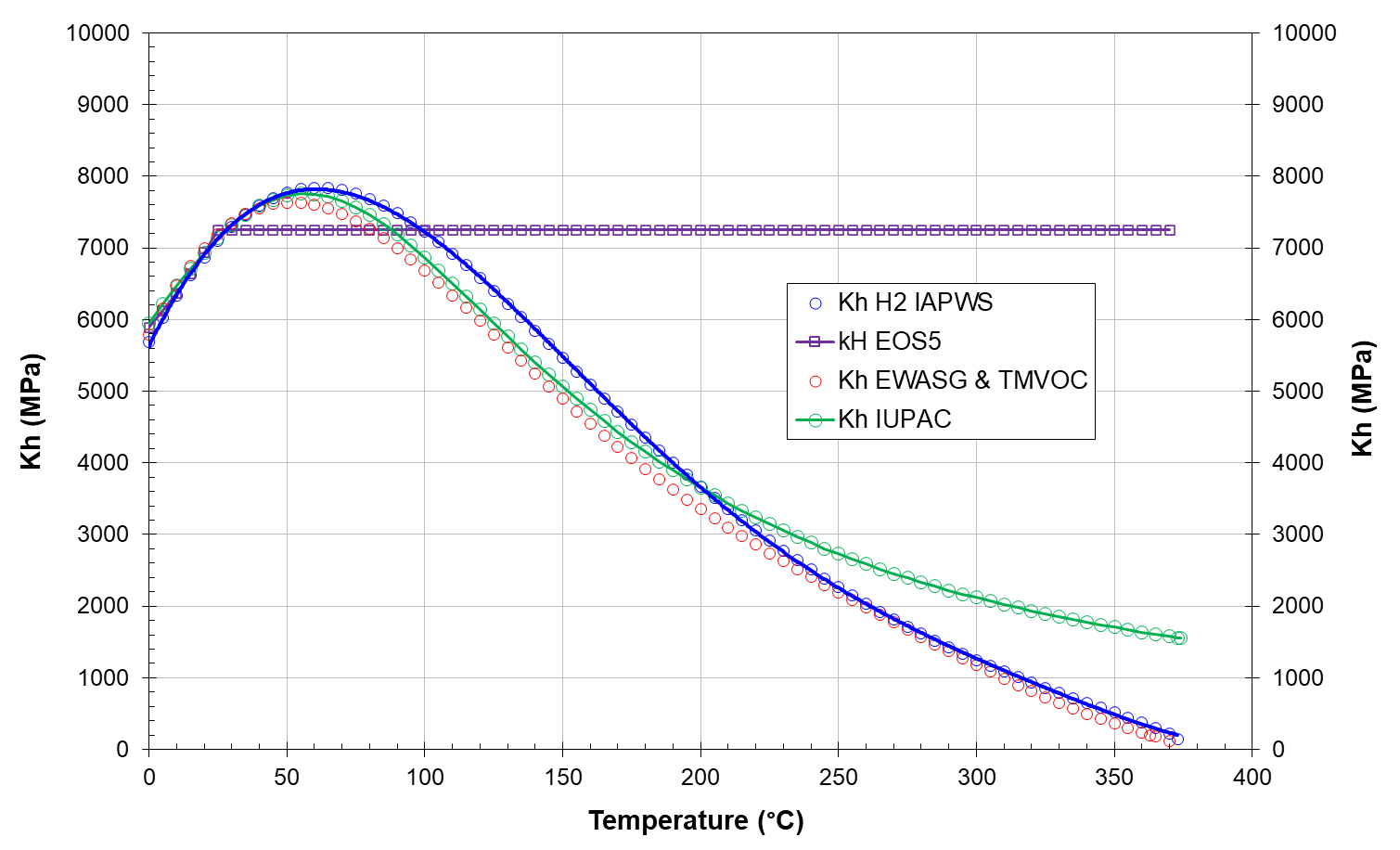

One of the major differences is in the H2 solubility in liquid water. In EOS5 there is a linear relationship for Henry's constant between 0 and 25°C, then the 25°C value is kept constant at T>25°C.

In EWASG H2 Henry's constant is a function of T from 0 to 370°C. The two Henry's constants are shown in the figure below.

In addition, in EOS5 the contribution of dissolved H2 on the enthalpy of aqueous phase is neglected, while in EWASG is accounted for. But H2 solubility is very low, so related effects should not be very important.

Another difference is related to the effects of dissolved salts, in EWASG simulated using NaCl as a proxy fro TDS. If the salinity in your aquifer is low (less than a couple tens of thousands ppm), the pure water properties of EOS5 are almost equivalent to the brine properties computed by EWASG. At higher salinities, you may start to see the differences between water and brine properties.

To have an idea of the reliability of EOS5 and EWASG EOS approaches in the calculation of phase properties at high H2 partial pressure, what I can suggest is to use the two EOS to compute H2 properties as function of P&T and then compare that properties to a suitable source, such as the on-line NIST calculator for fluid properties (https://webbook.nist.gov/chemistry/fluid/). In that way you may chose the more reliable EOS and have an idea about the approximations involved in using it.

Regards,

Alfredo

-

The T is changing at the injection element T1717:

T1715 34118 0.10028E+08 0.29773E+02 0.49812E+00 0.50188E+00 0.00000E+00 0.19998E-01 0.99632E+00 0.15183E-03 -.10815E+04 0.10000E+01 0.10125E+04

T1716 34119 0.10039E+08 0.27806E+02 0.54849E+00 0.45151E+00 0.00000E+00 0.20014E-01 0.99672E+00 0.15324E-03 -.11102E+04 0.10000E+01 0.10131E+04

T1717 34120 0.10059E+08 0.14330 E+02 0.61696E+00 0.38304E+00 0.00000E+00 0.20113E-01 0.99857E+00 0.16649E-03 -.11549E+04 0.10000E+01 0.10159E+04

T1718 34121 0.10039E+08 0.27808E+02 0.54845E+00 0.45155E+00 0.00000E+00 0.20014E-01 0.99672E+00 0.15324E-03 -.11102E+04 0.10000E+01 0.10131E+04

T1719 34122 0.10028E+08 0.29773E+02 0.49803E+00 0.50197E+00 0.00000E+00 0.19998E-01 0.99632E+00 0.15183E-03 -.10814E+04 0.10000E+01 0.10125E+04The T change is low because the mass injection rate is very low, only 0.015 kg/s

GENER----1----*----2----*----3----*----4----*----5----*----6----*----7----*----8

T1717A0001 0 0 0 1 COM3 1.500E-02 0.000E+00 0.000E+00By the way, you have not assigned the enthalpy for the injected H2, which is then taken equal to 0. J/kg by TOUGH2. You should evaluate the H2 enthalpy at injection conditios and use it in GENER.

I would also suggest using MOP(11)=2.